Hospitals and clinical diagnosis, Biomedical analysis laboratories, Blood banks and transfusion centers, Pharmaceutical and research laboratories, Toxicology centers, Biobanks, … iLsa, the sample storage system market leader, has developed the 3S Safe Sampling Systems to :

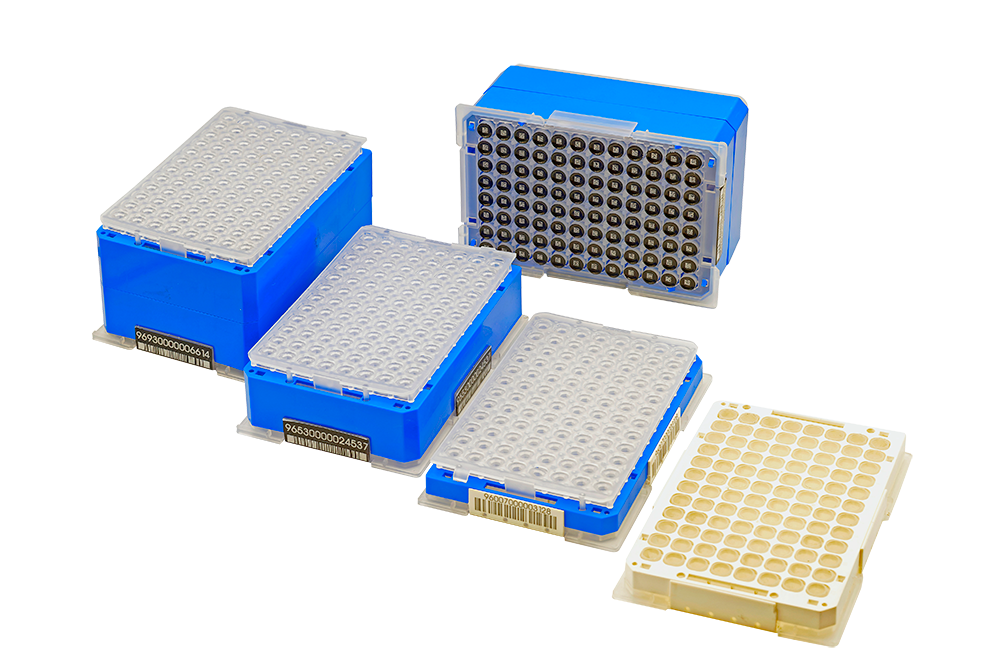

The originality of the 3s system (safe sampling systems) is its patented microplate. It is a monoblock microplate with extractible wells. The microplate is identified with a unique number printed in the factory (bar code) and each well is also identified with this same number to which is added its position on the microplate (DataMatrix). Each well has therefore its own unique identification. This original configuration simplifies your sample storage system management.

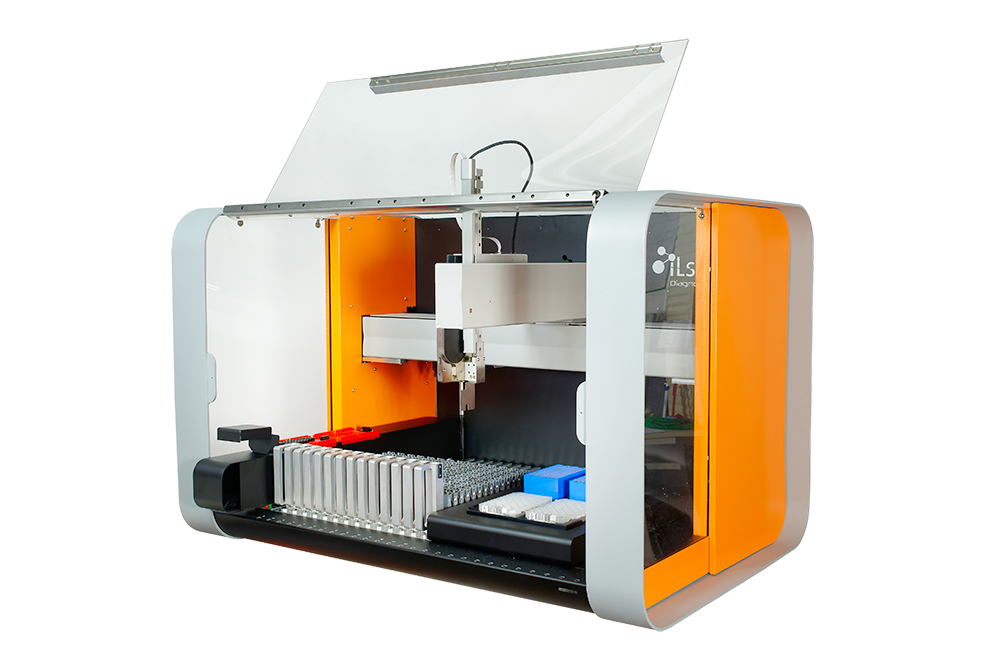

The system includes :

A few hours training is all that is required to train your operators. The system is controlled via a PC touch screen.

The use of disposable and capacitive tips allows to avoid any contamination and to check the aliquoted volume. Its anti-intrusion barrier, its MTBF and its intelligent sampling make this automat a reliable and robust device.

The management of primary tubes and microplates by barcodes and wells by DataMatrix avoid any human error.

This automated system is an essential element in obtaining your laboratory certification.

Neo Robot is a pre/post analysis automat. It can therefore be integrated at any stage in your total chain. It is connected to LIS/LIMS.

| Weight | 75 kgs |

| Sizes | Length : 114 cm, Width : 90 cm, Height : 98 cm |

| Capacity | 196 tubes, 4 microplates |

| Input | 3 sockets : 2 USB and 1 RJ45 ; 150 Watts |

| Mark | CE |

| HMI | PC with 23 inch touch screen |

iLsa designs and manufactures instruments and consumables (100% French). iLsa keeps in stock on its site in Besançon all the parts necessary to repair your device within 48 hours.

Your technician can directly contact our Hotline service technicians for online troubleshooting or to make an appointment at your location.

PARIS

7 Chemin de Saint-Hilaire

95310 SAINT-OUEN-L’AUMÔNE - FRANCE

Tél : +33(0)1 34 30 42 00